INITIATING SYSTEMS

We supply a range of initiating systems which consist of detonating cord connector clip attached to sealed end, with a marked color-coded label indicating the delay number and are available for various applications. LVC has the following initiating systems:

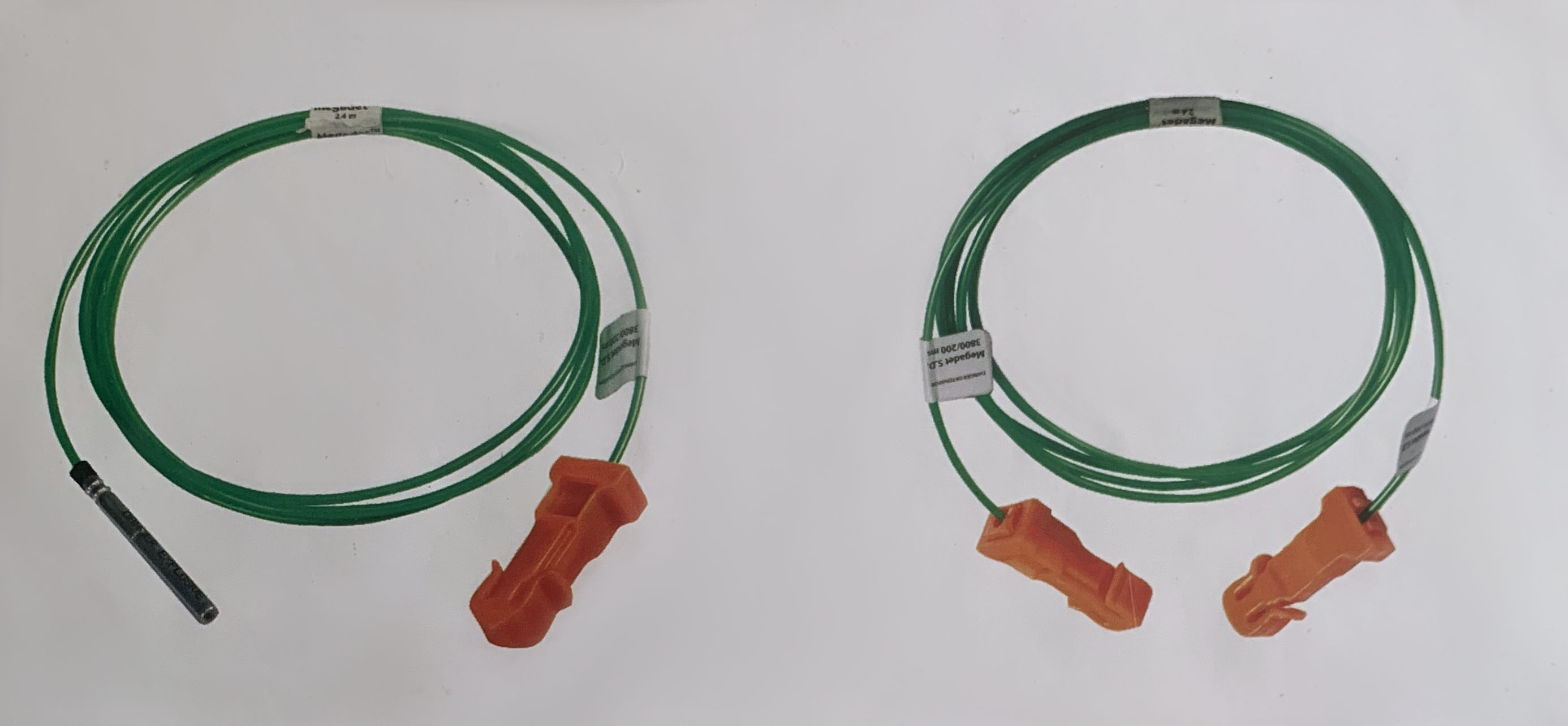

VIPERDET MS DOWN HOLE

VIPERDET MS DOWNHOLE assemblies consist of a specific length of green shock tube with a high strength delay detonator crimped to the one end and closed at the other end by means of an ultra-sonic seal. A color-coded label marked with the specific delay is attached to the shock tube within 10cm from the seal.

FEATURES

Detonator strength – No. 8.

Shock tube - double extruded polyethylene exterior over surly inner with a min 19kg tensile strength.

Water resistance – will function reliably in wet deep hole conditions.

Delay timing – two different delay timings (350ms, 500ms).

VIPERDET TRUNKLINE

VIPERDET Trunkline assemblies consist of a specific length of shock tube with a millisecond delay detonator crimped to the one end and closed at the other end by means of an ultra-sonic seal. A label marked with the specific delay is attached to the shock tube within 10 cm from the seal. Color coded labels are used to distinguish different delay assemblies from each other. A color-coded connector clip is attached to the detonator for easy connection to other shock tube assemblies. The connector can hold between 1 and 6 shock tubes and is designed to ensure easy connection, reliable initiation, while minimizing shrapnel damage to the shock-tube.

FEATURES

Detonator strength – No. 3.

Detonator shell – aluminum alloy.

Shock tube – double extruded, green in color.

Shock tube strength – resistant to abrasion and fully functional in hot and cold temperatures.

Shock tube - double extruded polyethylene exterior over surly inner with a min 19kg tensile strength.

Water resistance – will function reliably in wet deep hole conditions.

Delay timing – nominal delay timing of 17ms, 25ms, 42ms, and 67ms.

Connector – color coded to identify respective delay timing.

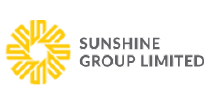

VIPERDET SD

VIPERDET SD assemblies consist of a specific length of green shock tube with a high strength delay detonator crimped to the one end and a low strength delay detonator crimped to the other end. A connector clip is attached to the low strength detonator, namely the surface detonator for easy connection to other shock tube assemblies. The connector can hold between 1 and 4 shock tubes and is designed to ensure reliable initiation, while minimizing shrapnel damage to the shock-tube.

<4>FEATURES Detonator strength – Low strength No. 3 surface detonator, No. 8 in-hole detonator.

Shock tube – extruded polyethylene exterior over surly inner with min 19kg tensile strength.

Water resistance – will function underwater if tube not damaged.

Delay timing – two different delay timings (out hole 200ms, in hole 3800ms).

Connector – T-clip ratchet connector.

VIPER BOOSTERS

VIPER BOOSTERS consist of an explosive charge of high strength and high detonation velocity, designed to be used in the explosive initiation sequence between an initiator or primer and the main charge, mostly non cap-sensitive blasting agents. Cast VIPER BOOSTERS are enclosed in a cylindrical printed shell and contain a mixture of RDX and TNT. A PETN capsule positioned internally near the detonator well ensures reliable initiation when using 3.6g/m detonating cord. A

FEATURES

Detonator strength – Low strength No. 3 surface detonator, No. 8 in-hole detonator.

Appearance – smooth and clean, with both ends covered.

Cap well and cord tunnel – smooth and straight with no distortion or blockage.

Velocity of detonation – minimum 8 000m/s.

Cast density – minimum 1.8 g/cm3.

Sensitivity – reliable initiation by standard detonator or 3.6g/m detonating cord.

Water resistance – retains sensitivity after being immersed in water at 100 PSI.

VIPERDET LP

VIPERDET LP assemblies consist of a specific length of green shock tube with a high strength delay detonator crimped to the one end and closed at the other end by means of an ultra-sonic seal. A detonating cord connector clip is attached to the sealed end, with a marked color label indicating the delay number. LP detonators can be initiated by a single strand of detonating cord with a loading strength from 3.6g/m to 8g/m. Color coded labels are used to distinguish different delay periods.A

FEATURES

Detonator strength – No.8.

Shock tube – green color, double extruded polyethylene.

Shock tube strength – resistant to abrasion and fully functional in hot and cold temperatures.

Delay timing – twenty different delay periods with no overlapping between adjacent delay number.

Connector – J-hook.